CQB-D stainless steel magnetic drive pump

Overview

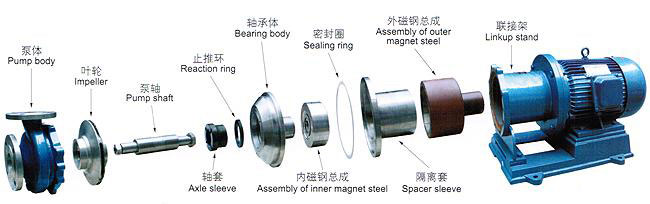

CQB-D stainless steel magnetic pump (referred to as magnetic pump) is usually composed of electric motor, magnetic coupling and corrosion-resistant centrifugal pump. Its main feature is that the magnetic coupling is used to transmit power without leakage. When the motor drives the outer magnetic steel of the magnetic coupling to rotate, the magnetic lines of force pass through the gap and the isolation sleeve and act on the inner magnetic steel to make the pump rotor rotate synchronously with the motor. , transmits torque without mechanical contact. At the power input end of the pump shaft, since the liquid is enclosed in the static isolation sleeve, there is no dynamic seal and thus there is no leakage at all.

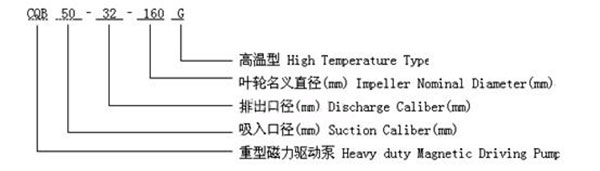

Model-Description

Application

Pump are made of stainless steel (304, 316L) material, it is widely used in chemical, petroleum, pharmaceutical, electroplating, environmental protection, water treatment, national defense, and other departments to transport inflammable, explosive, toxic and precious liquids, Make the working environment non-leakage, no pollution.

Structure diagram

Product parameters

| Model | Diameter(mm) | Flow (m³/h) | Head(m) | Motor Power (kW) | Voltage (V) | ||

| Import | Export | ||||||

| CQB-D32-20-125 | 32 | 20 | 3.2 | 20 | 1.1 | 380 | |

| CQB-D32-20-160 | 32 | 20 | 3.2 | 32 | 1.5 | 380 | |

| CQB-D40-25-125 | 40 | 25 | 6.3 | 20 | 2.2 | 380 | |

| CQB-D40-25-160 | 40 | 25 | 6.3 | 32 | 3 | 380 | |

| CQB-D40-25-200 | 40 | 25 | 6.3 | 50 | 5.5 | 380 | |

| CQB-D50-32-125 | 50 | 32 | 12.5 | 20 | 3 | 380 | |

| CQB-D50-32-160 | 50 | 32 | 12.5 | 32 | 4 | 380 | |

| CQB-D50-32-200 | 50 | 32 | 12.5 | 50 | 7.5 | 380 | |

| CQB-D50-32-250 | 50 | 32 | 12.5 | 80 | 18.5 | 380 | |

| CQB-D65-50-125 | 65 | 50 | 25 | 20 | 4 | 380 | |

| CQB-D65-50-160 | 65 | 50 | 25 | 32 | 7.5 | 380 | |

| CQB-D65-40-200 | 65 | 40 | 25 | 50 | 15 | 380 | |

| CQB-D65-40-250 | 65 | 40 | 25 | 80 | 18.5 | 380 | |

| CQB-D80-65-125 | 80 | 65 | 50 | 20 | 7.5 | 380 | |

| CQB-D80-65-160 | 80 | 65 | 50 | 32 | 15 | 380 | |

| CQB-D80-50-200 | 80 | 50 | 50 | 50 | 18.5 | 380 | |

| CQB-D80-50-250 | 80 | 50 | 50 | 80 | 37 | 380 | |

| CQB-D100-80-125 | 100 | 80 | 100 | 20 | 15 | 380 | |

| CQB-D100-80-160 | 100 | 80 | 100 | 32 | 18.5 | 380 | |

| CQB-D100-65-200 | 100 | 65 | 100 | 50 | 37 | 380 | |

| CQB-D100-65-250 | 100 | 65 | 100 | 80 | 55 | 380 | |

| Note: Each model can be equipped with explosion-proof motor | |||||||

Instructions for use

Installation and commissioning Instructions for use of CQB-D stainless steel magnetic drive pump:The CQB-D stainless steel magnetic pump should be installed horizontally and should not be erected. The plastic pump body should not bear the weight of the pipeline. For special requirements for vertical installation, the motor must be upward.

When the suction liquid level is higher than the pump axis line, just open the suction pipeline valve before starting. If the suction liquid level is lower than the pump axis line, the pipeline needs to be equipped with a bottom valve.

The CQB-D stainless steel magnetic drive pump should be inspected before use. The motor fan blades should be flexibly rotated, and there should be no jamming and abnormal noise. All fasteners should be tightened.

Check whether the rotation direction of the motor is consistent with the turning mark of the magnetic pump.

After the motor starts, slowly open the discharge valve. After the pump enters the normal working state, adjust the discharge valve to the required opening.

Before the CQB-D stainless steel magnetic pump stops working, the discharge valve should be closed first, and then the power supply should be cut off.

FAQ

Q1:What is the shipping way?

A4: For more details please contact us. Thank you.