G type screw pump

Overview

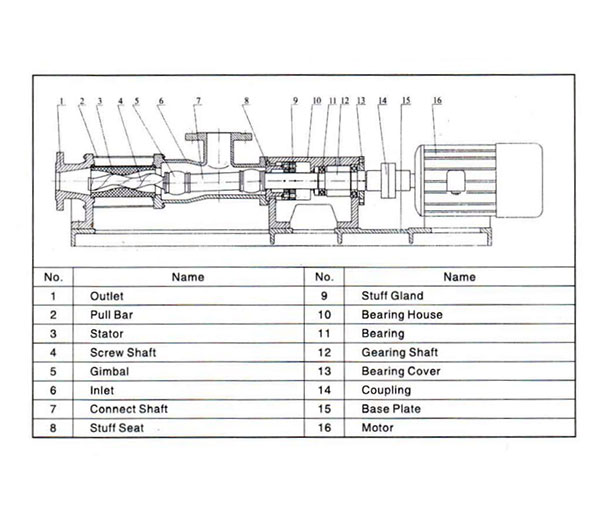

G-type screw pump is a new type of pump that works according to the principle of revolving meshing positive displacement. The main working parts of the G-type screw pump are the eccentric screw (rotor) and the fixed bushing (stator). G type screw pump adopts non-toxic and tasteless edible rubber, and the working temperature can reach 120 ℃. Due to the special geometry of the two parts, the openings respectively form separate sealed chambers. The medium is uniformly pushed and flowed from the axial direction. The internal flow rate is reduced and the volume remains the same. The pressure is stable, so there is no product swirl and agitation.

Application

Wide range of use: environmental protection, shipbuilding industry, petroleum industry, medicine, daily chemicals, food canning industry, brewing industry, construction industry, printing, paper industry, etc. and widely used in food metallurgy, papermaking, printing and dyeing, chemical industry, fertilizer and pharmaceuticals, etc. Used by the industrial sector.

Product Features

The pump has few parts, compact structure, small volume and easy maintenance. The rotor and stator are the wearing parts of the pump, and the structure is simple and easy to assemble and disassemble.

Product parameter table

|

Type

|

Cqpacity

|

pressure

|

Speed

|

Motor Power

|

NPSH

|

Inlet flange diameter

|

Outlet flange diameter

|

Allowable particle diameter

|

Allowable fiber length

|

|

(m³ / h)

|

(Mpa)

|

(r/min)

|

(kw)

|

(m)

|

(mm)

|

(mm)

|

(mm)

|

(mm)

|

|

|

G20-1

|

0.8

|

0.6

|

960

|

0.75

|

4

|

25

|

25

|

1.5

|

25

|

|

G25-1

|

2

|

0.6

|

1.5

|

32

|

25

|

2

|

30

|

||

|

G25-2

|

2

|

1.2

|

2.2

|

32

|

25

|

2

|

30

|

||

|

G30-1

|

5

|

0.6

|

2.2

|

50

|

40

|

2.5

|

35

|

||

|

G30-2

|

5

|

1.2

|

3

|

50

|

40

|

2.5

|

35

|

||

|

G35-1

|

8

|

0.6

|

3

|

65

|

50

|

3

|

40

|

||

|

G35-2

|

8

|

1.2

|

4

|

65

|

50

|

3

|

40

|

||

|

G40-1

|

12

|

0.6

|

4

|

80

|

65

|

3.8

|

45

|

||

|

G40-2

|

12

|

1.2

|

5.5

|

80

|

65

|

3.8

|

45

|

||

|

G50-1

|

20

|

0.6

|

5.5

|

4.5

|

100

|

80

|

5

|

50

|

|

|

G50-2

|

20

|

1.2

|

7.5

|

100

|

80

|

5

|

50

|

||

|

G60-1

|

30

|

0.6

|

11

|

5

|

125

|

100

|

6

|

60

|

|

|

G60-2

|

30

|

1.2

|

15

|

125

|

100

|

6

|

60

|

||

|

G70-1

|

45

|

0.6

|

720

|

11

|

150

|

125

|

8

|

70

|

|

|

G70-2

|

45

|

1.2

|

18.5

|

150

|

125

|

8

|

70

|

||

|

G85-1

|

65

|

0.6

|

15

|

150

|

150

|

10

|

80

|

||

|

G105-1

|

100

|

0.6

|

500

|

32

|

200

|

200

|

12

|

90

|

|

|

G135-1

|

150

|

0.6

|

400

|

32

|

200

|

250

|

12

|

90

|